We manufacture our products from A to Z

We communicate the Made in Italy label by producing coated abrasive tools for all branches. We infuse our values into what we produce: from the careful selection of certified and controlled materials to the manufacturing in our Italian factories.

From the production

The source materials used to produce Nastroflex abrasives are manufactured in our own production areas or in selected companies. We process the paper or cloth rolls to a process of electrostatic application of synthetic minerals.

The process, performed by plants structured in continuous lines, involves the application of two layers of adhesive, one spread before and one after the application of the mineral, and double drying in a tunnel. Each product must meet specific customer requirements in terms of quality and price.Abrasive products differ in composition, hardness and size of the grains used, which indicate the grit size, useful to determine the performance of the product and its areas of use. We use appropriate levels of antistatic on different products depending on the type of application.

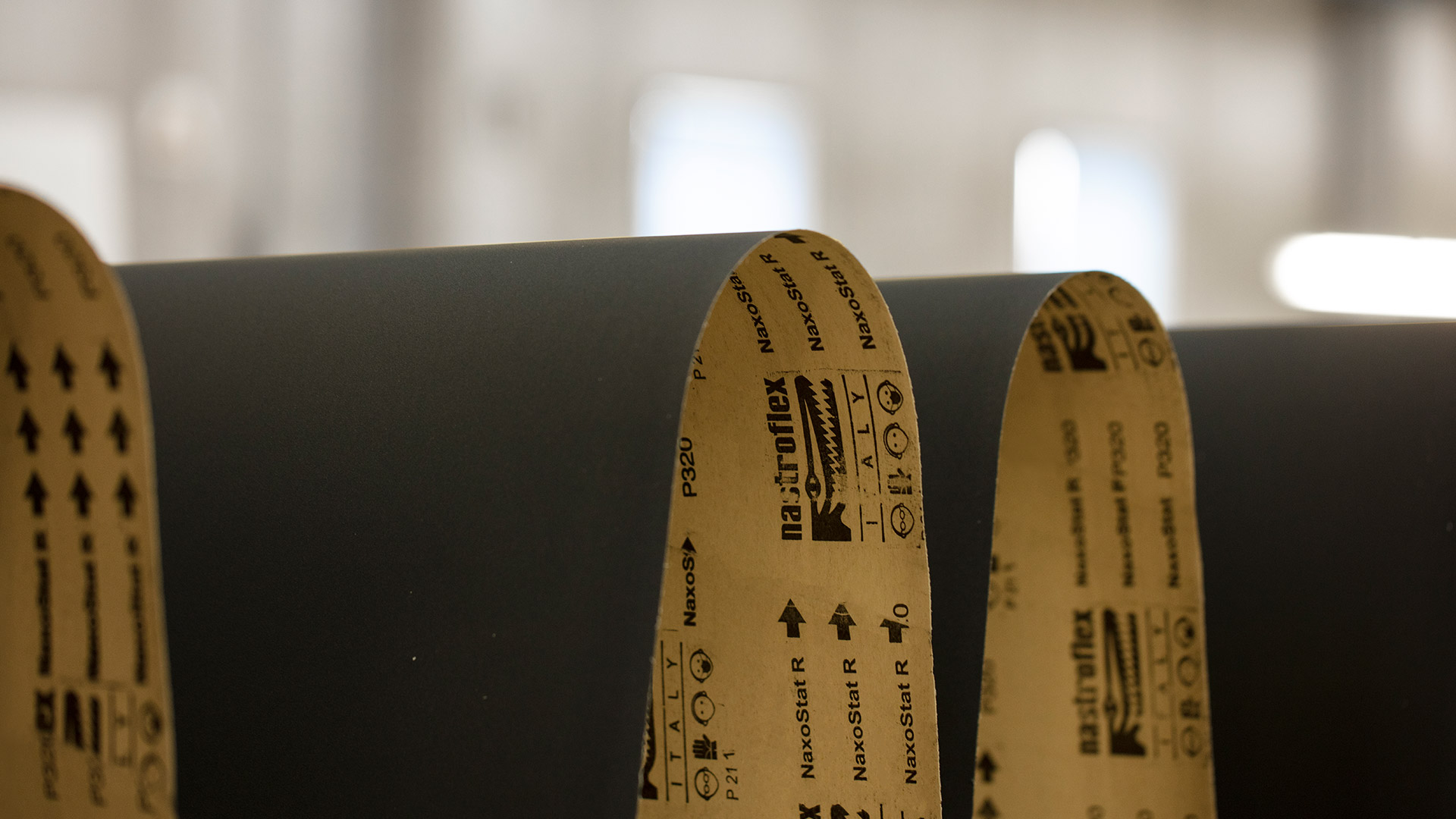

Into the convertion

We convert the raw material, stored in jumbo rolls. Depending on the job order, cuts are made by flexible machines capable of operating on jumbo rolls of different heights. The rolls are cut in length and prepared for the delicate joining stage.

The operations are carried out by special machinery and equipment, programmed by experienced staff. Once the in-line operations are completed, the products can be packed and placed in telescopic boxes by automatic systems.

We reduce the environmental impact of our products

How we do it:

- Choosing formaldehyde-free resins. Formaldehyde is one of the substances banned from furniture and panels generally used in residences and housing units because it may contain carcinogenic substances.

- Using recycled cardboard packaging to reduce the impact on forests. This choice allows us to actively contribute to deforestation reduction.

- We give customers the opportunity to order ‘bulk’ packaging that replaces individual boxes with one large pallet-sized box. This reduces the number of boxes used and simplifies packaging disposal.